Hair Dryer

Untethered.

Project Prompt

Traditional hairdryers are tethered to power outlets, limiting their portability and convenience. Recent advancements in battery technology present an opportunity to change that - this project's aim is to design a cordless hairdryer.

Understanding the Problem

I engaged in a variety of market and user research methods to build a sense of empathy and understanding for how people currently interact with their hairdryer. The focus at this stage was identifying pain points and user needs.

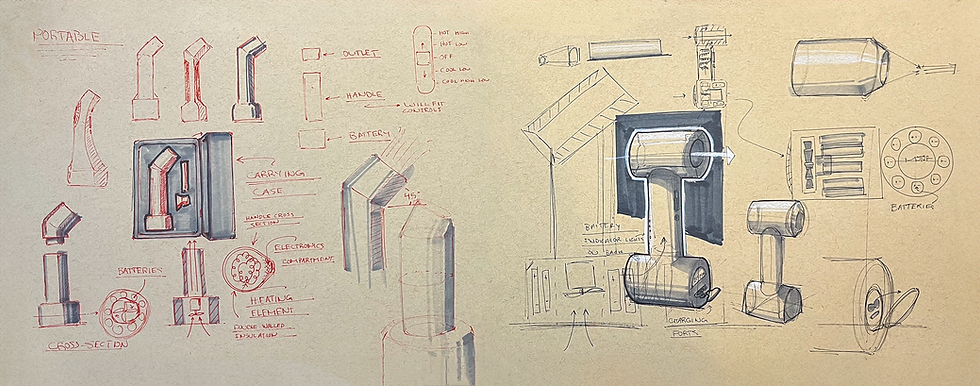

Ideation

I explored various concepts and landed on a design that prioritizes ease of use and a modern aesthetic. A cordless unit means repeated charging, so I accounted for that by designing a charging stand that would look nice on a counter.

Engineering Considerations?

Hairdryers are shockingly power-hungry machines. Thanks mainly to the heating element, typical dryers draw between 1000-2000 watts, which is close to the maximum output most US outlets can handle. Supplying that much wattage with a battery presents a significant engineering challenge in making the device also small and light enough to be useable.

Battery technology is advancing every day, and right now the best option for this application is a high-drain lithium battery pack.

Sanity check

-

5 mins runtime (at 1000 watts) = 0.083 [h] * 1000 [W] = 83.3 [Wh] required energy

-

Common voltage for high-drain Li batteries = 22.2 [V]

-

Required capacity = 83.3 [Wh] / 22.2 [V] = 3.75 [Ah]

-

Minimum battery requirements:

-

Battery energy > 83.3 [Watt-hours]

-

Battery capacity > 3.75 [Amp-hours]

-

Solution: 6 of them connected into a battery pack

Voltage = 22 [V]

Capacity = 4.5 [Ah]

Energy = 99.9 [Wh]

21700 Lithium-Ion Rechargeable Power Cell

Commonly used in drones, power tools, EV's, and more.

Note: High current wiring (ie. 6 or 8 AWG) and connectors will be essential to safely handle the ~45 [Amps]

Conclusion

While additional user research and engineering validation will be necessary to fully define design requirements and optimize battery performance, this analysis demonstrates that a viable solution is technically achievable within the project scope.

Prototyping

Because this was such an unusual form for a hairdryer, it was important to test out a physical model. I sketched through some ideas for how it could be built then created a works-like CAD model and fabricated a working prototype to put in front of users. At this stage, evaluating the overall fit and function were the priority so to save time and money it was easiest to power the prototype with a cord.

Learning From the Prototype

The physical model brought to life a couple issues that would need to be addressed if this design were to move forward:

1. The current form factor is too large for smaller hands to interact with the controls with one hand (many people brush with one, blow-dry with the other).

2. There is a chance that hair could be pulled in by the intake.

I plan to revisit this project in the future to address these issues but for the sake of this being a school project I kept moving for now.

CMF

Next I used Vizcom to to do some light CMF ideation.

I decided to go with a matte finish to avoid fingerprints and muted color tones to fit in with more bathroom interiors.

Renderings