Conformal 3D Printing

3D Printing For The Real World

Project Background

This project was the result of my admission into the University of Minnesota's MVP challenge, a semester long competition open to students, faculty, and staff to develop and present new technologies. I brought together a team of graduate Engineering and Design students to help design a 3d printer that could print onto non-flat surfaces.

Why?

The 3D printing Industry was valued at $24B in 2024 and is projected to reach $135B by 2033. [1]

FDM 3D printers hold the largest market segment of 3D printers, but are limited to printing in flat layers.

Increasing the functionality of FDM printers would capitalize on a growing demand for 3D printers.

Understanding The Problem

Our team conducted expert and user interviews across different industries to understand where this tech. could be most impactful.

Manufacturing

The Injection Molding (IM) industry is worth $261B and projected to grow 4% annually. [2]

There are strict design limitations for IM parts - draft, overhangs, thickness, feature depth, etc.

This process would enable features that are impossible to mold to be printed directly onto IM parts, combining the speed of IM and capability of 3DP

Construction / Architecture

The future of the $14T construction and architecture industries is in automation. [3, 4]

Applied to large-format printers (cement, clay, organics, etc.) this tech enables:

-

Designing into the natural landscape

-

Temporary structures and general conditions

-

Building repair and ornamentation

Medical

Custom:

-

Implants

-

Prosthetics

-

Orthopedic casts

Art

Conformal printers enable 3D artists to work at the intersection of the handmade, natural, and digital worlds like never before.

Other

Conformal printers have the potential in any industry that involves physical interaction - everything from Landscaping to Tattoos.

Concept

We developed a system pairing 3D scanning technology and custom non-planar slicing software with existing FDM 3D printers to achieve easily adaptable and widely applicable conformal 3D printing.

Scan the non-planar print surface

Orient 3D part model relative

to the print surface

Slice model with custom Algorithm

Send file to the

printer and print

Prototype

We chose to work with two printers: Creality Ender 5 Plus and FLSun SuperRacer. In the end, the build volume of the Ender 5 suited our needs best.

We redesigned the extruder gantry to mount a 3D scanner (Revopoint Range 2), and I wrote a custom G-code script to create a 3D model of anything placed in the build volume

The Software

I used rhino and Grasshopper to build a custom slicer that would intake the scanned surface and the print object, and then create the conformal G-code for the printer.

Proof of Concept

The Pitch

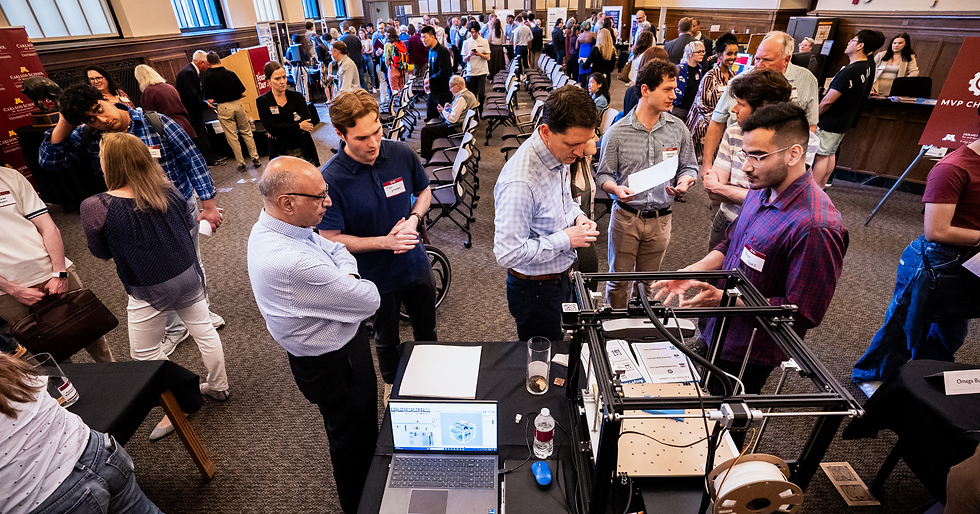

We featured out prototype and presented on our concept at the University of Minnesota's Founder Day.

.png)